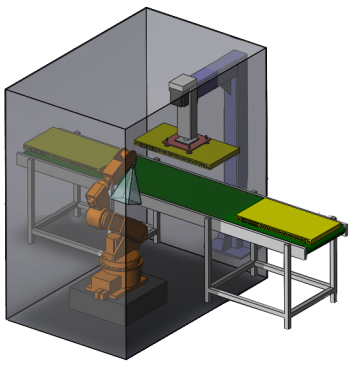

视觉检测 Machine Vision-I

自主研发的机器视觉外观检测系统,是一款适用于产品外观缺陷检测的智能设备。该设备由机器人根据预先设定的程序在不同位置对产品的不同部位拍照,进行视觉检测。检测信息由软件进行同步分析,最终输出外观缺陷检测结果。本产品有效减少人为判断的失误,大幅度提高外观缺陷检测的效率和准确度。

产品特点:

机器视觉外观检测系统巧妙融合了运动控制、视觉检测与自动化技术,让外观缺陷检测过程更方便、更高效、更智能。

定制化服务:可以根据客户需求定制,为客户提供不同检测项目的产品。

高质高效:设备可快速自动检测、上下料,对设备进行6个面的外观缺陷检查,并提供界面供用户方便地查询产品的故障具体位置。

简单易懂:窗口编辑皆为对话框方式交互,用户可根据检测需要,最多可对4个窗口进行编辑,操作简便。检测数据可以自动计算统计值并绘制成直方图或趋势图,方便用户分析数据。

集成度高:设备支持常用的数字图像处理算法,算法顺序执行,每个窗口最多可叠加6种预处理算法。用户可以对检测结果进行任意组合并独立指定输出方式,包括GPIO输出、RS232输出、网络输出。

灵活可变:针对不同尺寸的产品,该设备可示教并自适应。技术员可通过编程界面对新型号产品进行编程。

安全可靠:暗箱内进行检测,确保检测过程的安全、准确、可靠。

产品参数及系统构成:

工作环境 | 工作温度 | 0℃~45℃ |

存储温度 | -40℃~80℃ | |

湿度 | 5%~95%相对湿度, 无冷凝 | |

通信接口 | USB | USB2.0×6 |

以太网 | GigEx2 | |

串口 | RS232x6 | |

I/O接口 | GPIOx8(5V DC) | |

检测精度 | 尺寸测量 | 精度0.001mm |

定位精度 | 精度0.02mm | |

检测算法 | 边缘检测 | 指定区域内提取直线、圆形、圆弧、点 |

斑点测量 | 指定区域内斑点数量和面积 | |

斑点测量S | 圆形或圆环区域内是否存在缺陷 | |

斑点测量D | 圆形或圆环边缘是否存在凹凸缺陷 | |

尺寸测量 | 对已经编号的元素进行几何关系测量 | |

形状匹配 | 测量图形的位置、角度等信息 | |

节距测量 | 指定区域内多个边缘间距离 的最大、最小、平均值 |