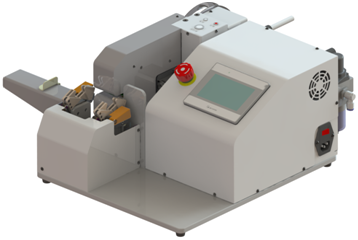

BM-Taper-I-A

一款针对多点、有准确定位要求的自动捆扎机,适合9/19mm宽的胶带,可与夹持机构配合,实现自动捆扎。该设备包扎效果稳定、定位精准,可根据客户需求衍生出多种捆扎设备。

产品特点:

该机器让捆扎更准确、更方便、更高效、更可靠。

衍生设计:机头可与控制柜分离,可根据客户需求定制,衍生出绞线机捆扎、机器人捆扎等衍生设备

圈数可调:设备可实现2-6圈捆扎

定位精准:

位置精度为±2mm,可与定制的夹爪配合,更加贴近护套端面

生产效率高:

由于捆扎过程为自动操作,可提升综合捆扎效率,设备兼有计数功能。

捆扎质量高:

捆扎后表面平整,质量可靠。

操作简单:

操作者仅需把线束放进治具内,触发开关即可完成所有点位的自动捆扎。

产品参数

设备尺寸: 450x475x220mm

输入电压: 110V/220V AC (±10%)

供气压力: 0.6-0.7 MPa

最大功率: 120W

胶带宽度: 9mm (-A9 )

19mm (-A19)

线束直径: 8mm以下或定制

包胶圈数: 2-6圈

包胶转速: 1000 rpm

胶带卷直径: ≤150mm

胶带轴直径: 32mm~76mm

胶带材质: PVC、布纤维等